Amateur Machinist: Tuning Lever Extension

Category: Shop ProceduresDate: 2021-11-05

A practical project

I'm a woodworker, but I am fascinated by what machinists can do. Three years ago, an old Atlas metal lathe came home with me and I acquired a few skills using it. After those projects it became clear that a milling machine would be the next piece of equipment in the metal working corner of my shop. That milling machine is a Grizzly Mill/Drill with digital read out. Today I completed a very practical project: an extension for a piano tuning lever.

A video is worth at least a thousand words:

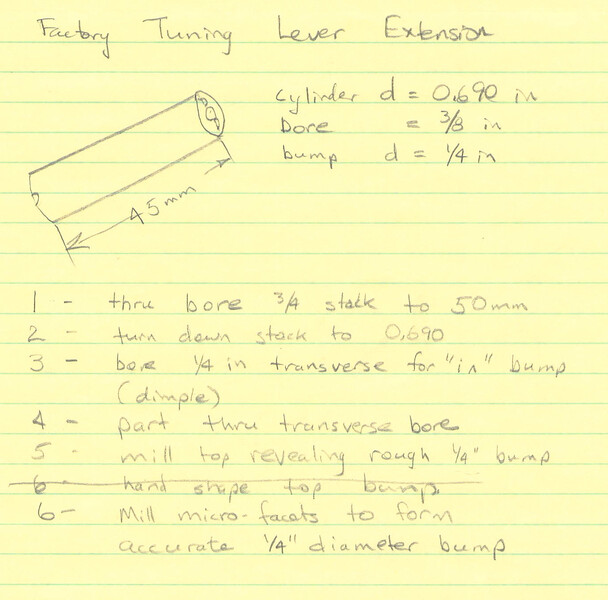

I began by writing out the specs and order of operations for the project:

To clarify: 1. Using 3/4" round steel rod, bore lengthwise through the rod on the lathe to a depth of 50 mm. 2. On the lathe, reduce the diameter of the stock to 0.690 inches (11/16") to match the diameter of the original tool components. 3. At one end of the rod, on the milling machine bore a transverse hole 1/4" inch in diameter. This will be used for the negative detent. 4. Back at the lathe, part off (cut through) the rod, bisecting the 1/4" diameter hole. This will form the half-round negative detent on the bottom of the piece. 5. At the milling machine mill down 1/8 inch shoulders on the top of the piece leaving a 1/4 inch wide by 1/8" tall bump for the positive detent. 6. Here I changed my approach. I had thought that I'd hand file the rectangular bump of the top detent, forming an approximate half-round detent. But I changed my thinking and decided to use some trigonometry and the digital readout on the mill. I calculated offsets for 36 cuts to form that little half round. Manual machinists of the world: How would you have done it?

Here's the result:

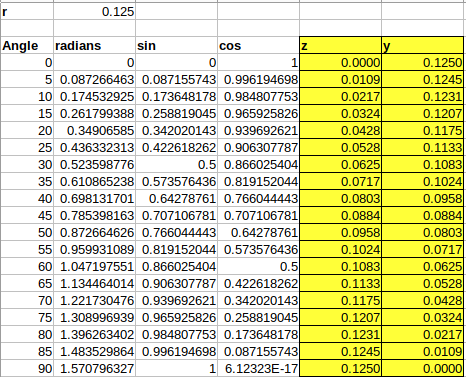

Making that positive detent was the brain teaser for me. As I thought about it though, I realized that it could be done on the milling machine with the tools at hand. In other words, it could be formed with an end mill, if the cuts were small enough. I chose to divide the half-circle into 36 equal arcs which would produce an approximate half circle of 36 facets. It worked out the first time with lots of attention to the digital readout for setting the vertical and horizontal placement of the cutter head. This is my spreadsheet for tool positioning:

The improved tool:

My machine shop corner:

Followup:

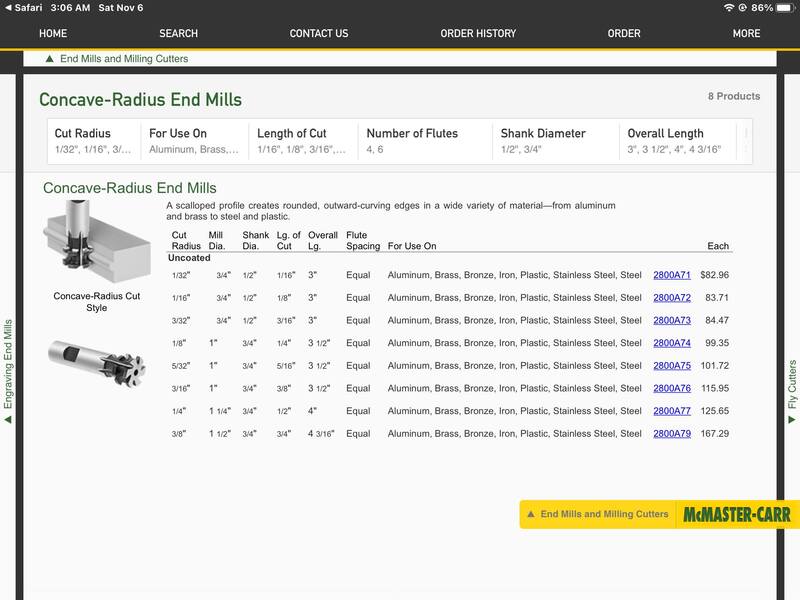

Don Teach, piano technician and machinist, kindly showed me that I could have bought a concave cutter to form the positive detent.

One thing I've been learning about this stuff is there's always something else to buy!

2025 2024 2023 2022 2021 2020 2019 2018 2017 2016 2015 2014 2013 2012 2011 2010 2009 2008 2007 2006 2005 2004

Comments

I welcome your comments. You do NOT need to sign in to leave a comment. If you create an account and sign in, my comment system will notify you of replies to your comment. Thanks for stopping by.--Duane McGuire